Welding Flux-Cored Rods💪💪

Welding Flux-Cored Rods💪💪

Regular price

Rs. 890.00

Regular price

Rs. 1,400.00

Sale price

Rs. 890.00

Unit price

per

Couldn't load pickup availability

From Amateur To Pro.

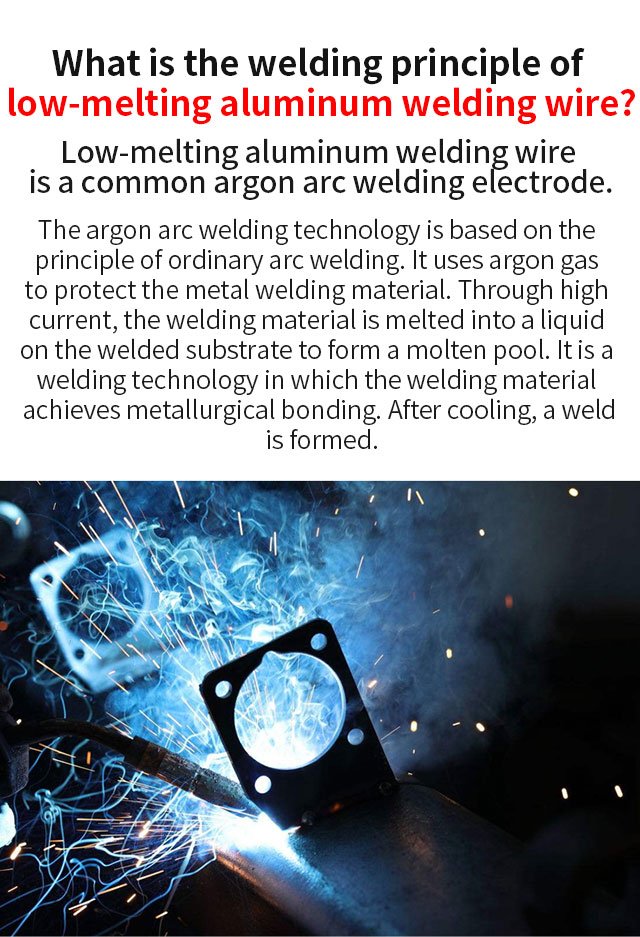

Regardless of your prior experience, anyone can weld aluminum without the need for expensive equipment like welding machines. All you need is a simple propane torch and some easy welding rods.

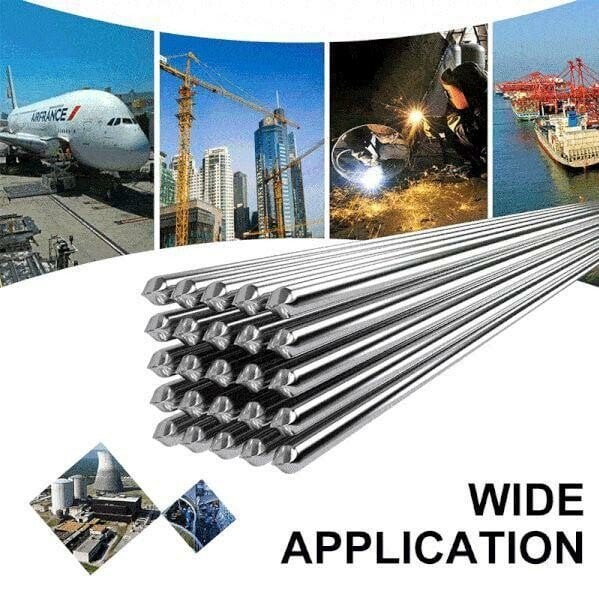

Every aspect of Solution Welding Rods are designed for the pursuit of performance to be the world's best in class?in Aluminum and other non-ferrous materials repair.

Product Features:

- The easy-to-melt welding?rods are?high-quality special?rods that are mainly used for welding / brazing aluminum and aluminum alloys.?However, they can also be used for hard welding non-ferrous metals other than stainless steel.

- Recommended for welding aluminum alloys: 1060, 1350, 3003, 3004, 3005, 5005, 5050, 6053, 6061, 6951, 7005 and cast alloys 710.0 and 711.0

- Applications include cargo areas, loading ramps, docks, diamond plates, irrigation lines, engine blocks, gearboxes, etc.

- Prepared for small repairs.?For repairs that would compromise safety if they are not repaired, we recommend replacing the parts completely instead of repairing them.

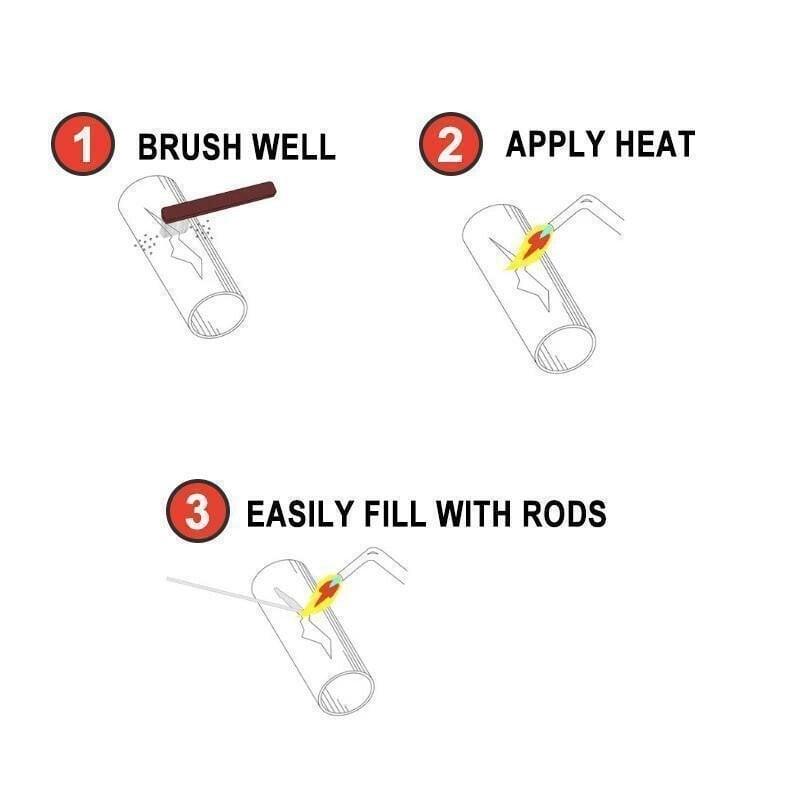

Welding Instructions:

- Through physical cleaning, polishing the surface, cleaning the grease on the surface of the weld, and using a steel brush or copper brush to remove the plating layer, etch, paint, oil, oxide and other coatings.

- Heat the surface of the base metal at the welding place (do not directly burn the electrode) until the temperature reaches 550 degrees, the working temperature of the welding wire. When the surface temperature of the base metal is sufficient, the welding wire can flow and penetrate to the Jinzhan capillary well.

- When repairing thin aluminum parts, just heat the aluminum base material to a suitable working temperature, and then use the welding wire to friction and fuse to form a weld. Only the gold high brush melted welding wire is used to fill the weld to form a weld.

Caution:

- The surface of the base material must be cleaned and dried, that is, clean and welded. (Cleaning up the surface of the base material refers to the removal of electroplating, corrosion, paint, oil, oxide, etc.)

- The temperature of the base metal must reach 550¡ãC, including the temperature of the base metal during the welding process, should be kept at about 550¡ãC.

- Never apply heat directly to the rod as it will crumb,and if you manage to melt the rod directly, the weld will be easily breakable.?Remember, melting the rod directly is a wrong way, and makes crumby welds.

Just a?few?of the many parts that can be?easily?repaired!

??Aluminum Heads |

??Fuel Tanks? |

??Cast Iron Heads |

??Manifolds |

??A/C Lines |

??Fenders |

??Truck Beds |

??Transmission Cases |

??Radiators |

??Generators |

??Pot Metal Parts |

??Irrigation Pipes |

??Refrigeration |

??Rivets |

??Condenser Lines |

??Aftercoolers |

??Industrial Parts |

??Aluminum Molds |

??Truck Beds |

??Timing Covers |

???Mast |

??Complete Fabrication?? |

??Tool Boxes |

??Aluminum Boats |

??Seams |

??Towers |

??Ladders |

??Cavitation Plates |

Specifications:

- Material:?Al-Si Alloy

- Color:Silver

- Melting point:400

- Working temperature:?400-450

- Uses:luminum aluminum welding

- Weight:10PCS(30g)/20PCS(50g)

- Size:?33cm*10/20Pcs.(According to the?manual measurement, there may be a subtle deviation.)